John Deere 7000 Series Tractor Evolution

John Deere Evolution is a visually stunning work that blends tractors photographed in custom-built studios with concept drawings and behind-the-scenes looks at how the machines were designed and built. This encyclopedic history covers every model line built by John Deere since 1919. In this excerpt from the book, read about the creation of the 7000 Series.

While the 6000 series was being developed, the Waterloo-based Deere team was busy creating the higher-horsepower 7000 series.

The new TechCenter cab debuted on the 7000 series with improved visibility and sound reduction, as well as digital display panels. The console was extensively redesigned and allowed easier control of the machine. The transmission was also the new nineteen-speed Power Shift (one more than the pesky competition’s new powershift unit).

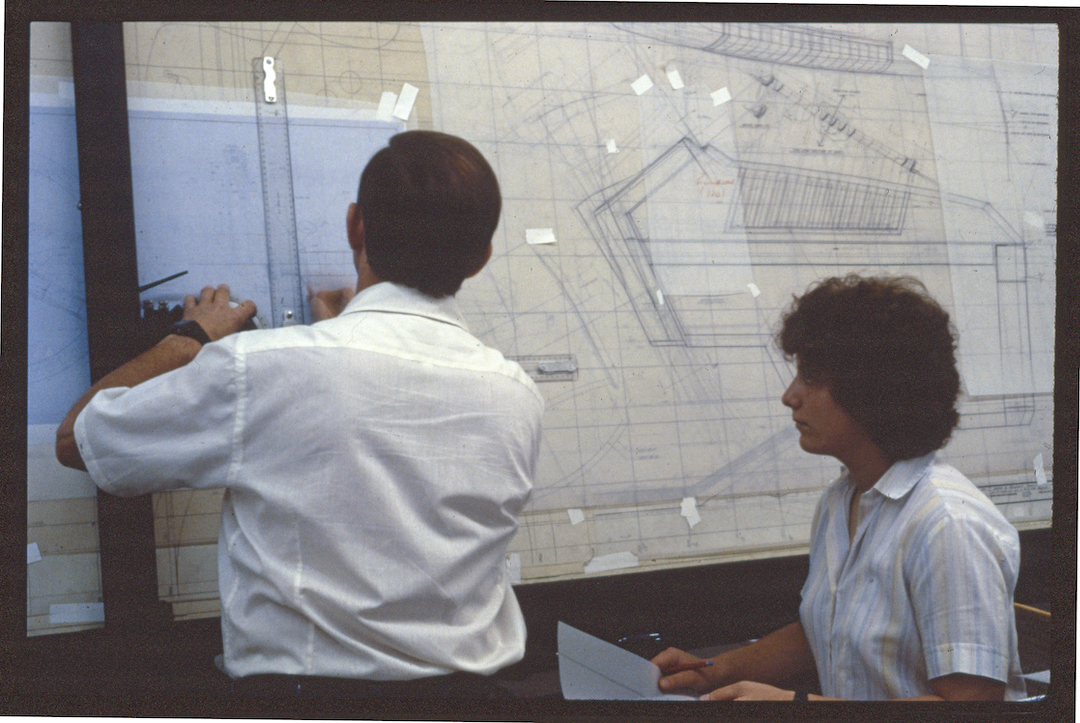

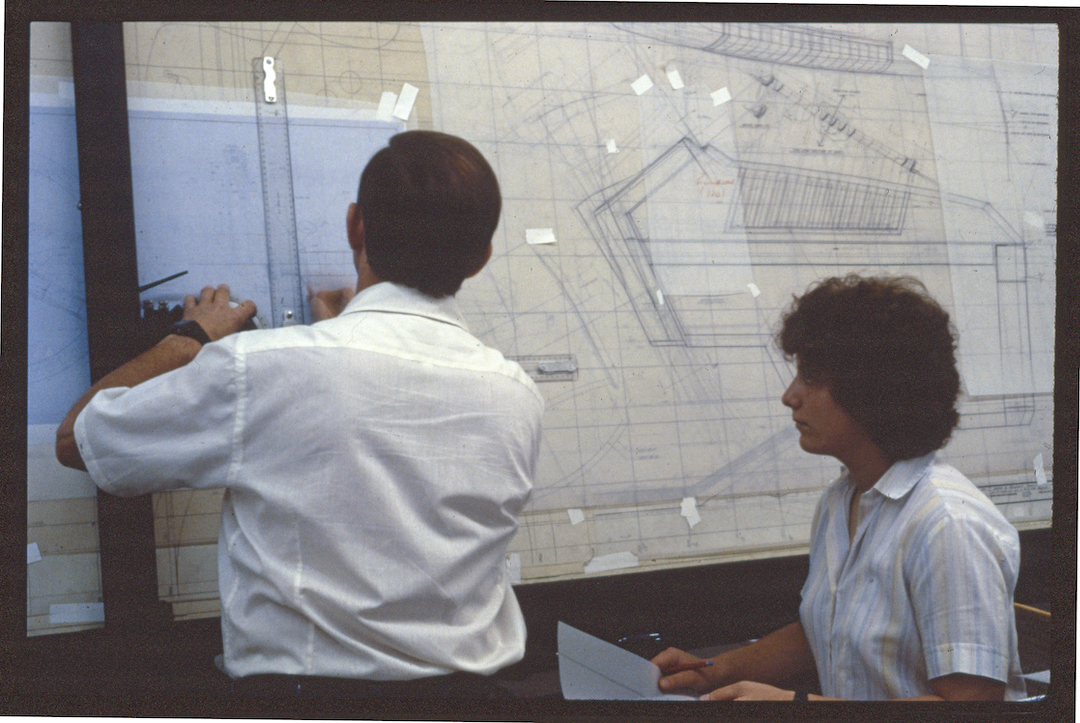

The new 7000 was an all-new design penned by Henry Dreyfuss Associates. Dan Nichols and Ms. Fructus at HDA are shown here drawing on a new hood design. Photo courtesy of Henry Dreyfuss Archive, Cooper Hewitt, Smithsonian Design Museum.

The new 7000 was an all-new design penned by Henry Dreyfuss Associates. Dan Nichols and Ms. Fructus at HDA are shown here drawing on a new hood design. Photo courtesy of Henry Dreyfuss Archive, Cooper Hewitt, Smithsonian Design Museum.

William Crookes was an industrial designer at Henry Dreyfuss and Associates (HDA) who worked on the John Deere account for many years. He said that while Bill Hewitt was CEO at Deere, the communication between John Deere and HDA was outstanding, and that they were involved from the beginning to the end of the process. He said that the process was quite different by the time the 7000 series was developed.

When the 7000 series was conceived, the process began with a meeting at which the parameters were defined. Crookes said the engineering team had more say than in the past. “We would get the group together and define the givens. And when we did that, a lot of times it was how agreeable the Deere engineers would be to the next generation of appearance,” Crookes said. “From time to time they would not agree on things like what finger protection you need downstream over the fan, the cooling fan.

The new 7000 series featured a modular design that no longer used the engine as a stressed member of the frame. Photo courtesy of Henry Dreyfuss Archive, Cooper Hewitt, Smithsonian Design Museum.

The new 7000 series featured a modular design that no longer used the engine as a stressed member of the frame. Photo courtesy of Henry Dreyfuss Archive, Cooper Hewitt, Smithsonian Design Museum.

“They also changed CEOs, so we did not have a line of communication, and neither did we have the PRMs that reviewed the design proposals and configurations. We lost that link and then it was up to whatever the powers within each design group to determine what was pertinent for that generation of tractor design.”

Crookes suggested that this process allowed the continuity of design found on older series to start to fail. He said he saw that in the case of the 7000 series, when Ron Burk at Waterloo led a very ambitious redesign.

The pivoting front axle is featured in this shot of the smallest member of the line, the Model 7600. Photo courtesy of Henry Dreyfuss Archive, Cooper Hewitt, Smithsonian Design Museum.

The pivoting front axle is featured in this shot of the smallest member of the line, the Model 7600. Photo courtesy of Henry Dreyfuss Archive, Cooper Hewitt, Smithsonian Design Museum.

“There was a very handsome design . . . done by Ron Burk in Waterloo,” Crookes said. “It centered around relocation of the cooling package. And ultimately it was produced and was well received, but not everybody could move their cooling package in the same way that the 7000 could. So that configuration was limited to the 7000s and couldn’t be applied to the 8000s or the 9000s. So the whole design continuity started to fall apart.

“We got our arms twisted a number of times to be agreeable and let’s do this. So we did it and ultimately wound up with this sort of discombobulated appearance of things.”

The biggest model of the line was tested at Nebraska from May to July 1993. On most Deere tractors, the test results exceed the rating, and the 7800 was no exception. The tractor was rated for 145 PTO horsepower, and put out 159 in Nebraska test 1668. Photo courtesy of Henry Dreyfuss Archive, Cooper Hewitt, Smithsonian Design Museum.

The biggest model of the line was tested at Nebraska from May to July 1993. On most Deere tractors, the test results exceed the rating, and the 7800 was no exception. The tractor was rated for 145 PTO horsepower, and put out 159 in Nebraska test 1668. Photo courtesy of Henry Dreyfuss Archive, Cooper Hewitt, Smithsonian Design Museum.

Grab your own copy of John Deere Evolution to keep reading.

While the 6000 series was being developed, the Waterloo-based Deere team was busy creating the higher-horsepower 7000 series.

The new TechCenter cab debuted on the 7000 series with improved visibility and sound reduction, as well as digital display panels. The console was extensively redesigned and allowed easier control of the machine. The transmission was also the new nineteen-speed Power Shift (one more than the pesky competition’s new powershift unit).

The new 7000 was an all-new design penned by Henry Dreyfuss Associates. Dan Nichols and Ms. Fructus at HDA are shown here drawing on a new hood design. Photo courtesy of Henry Dreyfuss Archive, Cooper Hewitt, Smithsonian Design Museum.

The new 7000 was an all-new design penned by Henry Dreyfuss Associates. Dan Nichols and Ms. Fructus at HDA are shown here drawing on a new hood design. Photo courtesy of Henry Dreyfuss Archive, Cooper Hewitt, Smithsonian Design Museum.William Crookes was an industrial designer at Henry Dreyfuss and Associates (HDA) who worked on the John Deere account for many years. He said that while Bill Hewitt was CEO at Deere, the communication between John Deere and HDA was outstanding, and that they were involved from the beginning to the end of the process. He said that the process was quite different by the time the 7000 series was developed.

When the 7000 series was conceived, the process began with a meeting at which the parameters were defined. Crookes said the engineering team had more say than in the past. “We would get the group together and define the givens. And when we did that, a lot of times it was how agreeable the Deere engineers would be to the next generation of appearance,” Crookes said. “From time to time they would not agree on things like what finger protection you need downstream over the fan, the cooling fan.

The new 7000 series featured a modular design that no longer used the engine as a stressed member of the frame. Photo courtesy of Henry Dreyfuss Archive, Cooper Hewitt, Smithsonian Design Museum.

The new 7000 series featured a modular design that no longer used the engine as a stressed member of the frame. Photo courtesy of Henry Dreyfuss Archive, Cooper Hewitt, Smithsonian Design Museum.“They also changed CEOs, so we did not have a line of communication, and neither did we have the PRMs that reviewed the design proposals and configurations. We lost that link and then it was up to whatever the powers within each design group to determine what was pertinent for that generation of tractor design.”

Crookes suggested that this process allowed the continuity of design found on older series to start to fail. He said he saw that in the case of the 7000 series, when Ron Burk at Waterloo led a very ambitious redesign.

The pivoting front axle is featured in this shot of the smallest member of the line, the Model 7600. Photo courtesy of Henry Dreyfuss Archive, Cooper Hewitt, Smithsonian Design Museum.

The pivoting front axle is featured in this shot of the smallest member of the line, the Model 7600. Photo courtesy of Henry Dreyfuss Archive, Cooper Hewitt, Smithsonian Design Museum.“There was a very handsome design . . . done by Ron Burk in Waterloo,” Crookes said. “It centered around relocation of the cooling package. And ultimately it was produced and was well received, but not everybody could move their cooling package in the same way that the 7000 could. So that configuration was limited to the 7000s and couldn’t be applied to the 8000s or the 9000s. So the whole design continuity started to fall apart.

“We got our arms twisted a number of times to be agreeable and let’s do this. So we did it and ultimately wound up with this sort of discombobulated appearance of things.”

The biggest model of the line was tested at Nebraska from May to July 1993. On most Deere tractors, the test results exceed the rating, and the 7800 was no exception. The tractor was rated for 145 PTO horsepower, and put out 159 in Nebraska test 1668. Photo courtesy of Henry Dreyfuss Archive, Cooper Hewitt, Smithsonian Design Museum.

The biggest model of the line was tested at Nebraska from May to July 1993. On most Deere tractors, the test results exceed the rating, and the 7800 was no exception. The tractor was rated for 145 PTO horsepower, and put out 159 in Nebraska test 1668. Photo courtesy of Henry Dreyfuss Archive, Cooper Hewitt, Smithsonian Design Museum.Grab your own copy of John Deere Evolution to keep reading.